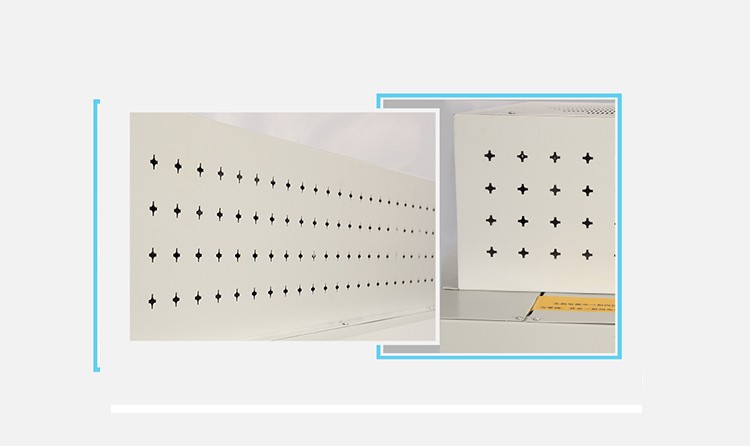

YASON Automatic High Speed Heat Thermal Film Shrink Sleeve Cutter Tunnel Wrapping Packaging Machine For Water Wine Juice Bottles

Introduction:

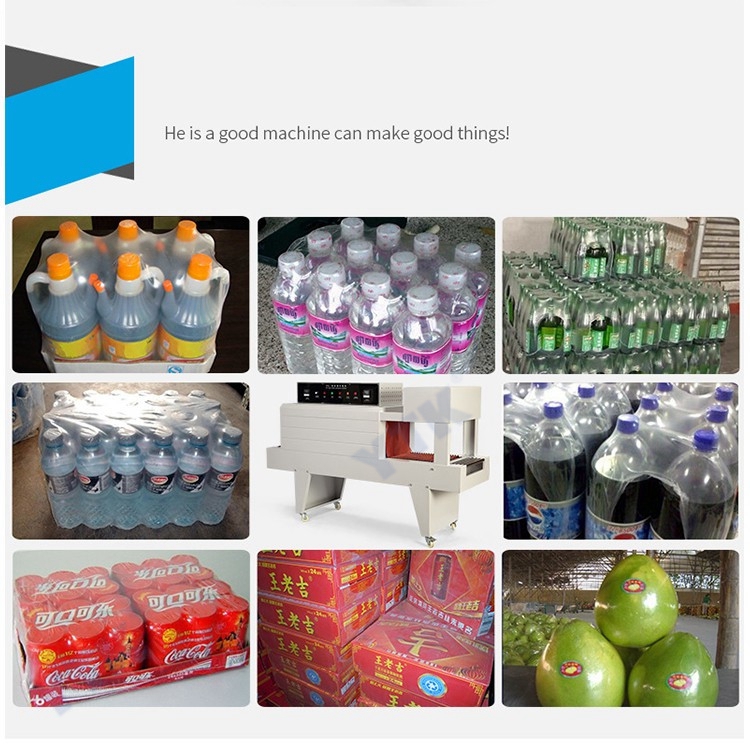

Heat shrinkable packaging is one of the more advanced packaging methods in the market. It is wrapped around the product or package by shrink film. After heating, the shrink film is wrapped around the product or package to fully display the appearance of the product, improve the product's marketing performance, and increase the appearance. A sense of value. At the same time, the packaged articles can be sealed, moisture-proof, and anti-pollution, and the sheets are protected from external impacts, and have a certain cushioning property, especially when the package is fragile, which can prevent the containers from scattering when scattered, and can also reduce the products.

Technical Parameters:

Product Details:

1. Electronic constant temperature control

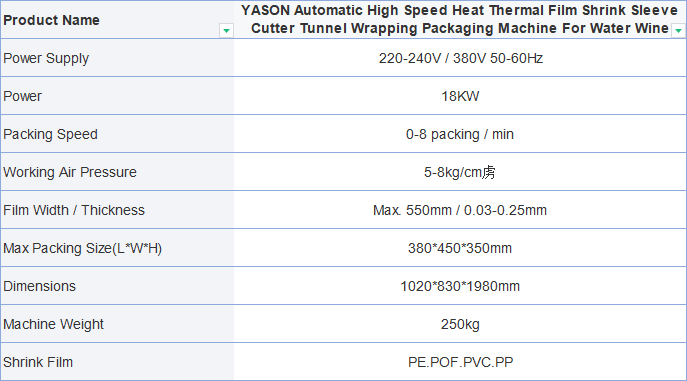

The quartz tube heating method can continuously generate heat during work, and the powerful wind circulation can make the heating temperature more uniform. At the same time, the electronic temperature control system is stable in the temperature of the shrinking furnace and saves electricity.

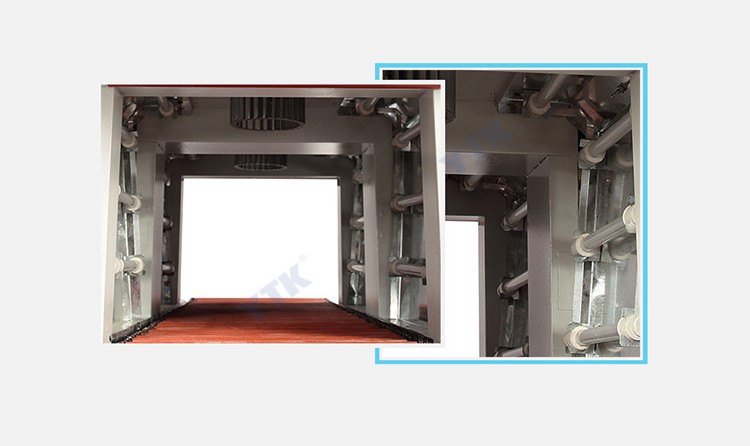

2. Double big leaves

The interior is equipped with two double large blades, which makes the wind in the shrinking furnace stronger, heating faster and shrinking more evenly.

3. High power cooling fan

Equipped with high-power outlet chiller, professional plasticity, instant shaping, making the contraction more firm and uniform.

4. Roller conveyor

The drum conveyor is installed at the exit, which is convenient for cargo transportation and convenient for conveying and handling

products.

5. Easy control panel

Simple and convenient operation panel makes operation safer and clear at a glance, no need to worry about encountering complicated

operation procedures.

6. Large size material entrance

The material inlet is designed with a large size and the high temperature cloth is used as the occlusion at the entrance.

7. Multiple exhaust hole heat dissipation design

The back of the control box adopts multiple venting holes to ensure heat dissipation of electrical components, enhance product

life, and can work continuously for a long time.

Application:

Contact: Jane Huang

Phone: 86-13677086494

E-mail: jane@ytkpackage.com

Whatsapp:0086-13677086494

Add: Wenzhou City, Zhejiang Province, Ouhai District, South White Elephant Jinzhu Industrial Zone, 408-1 Xia Jin Road

We chat